Mainstream fashion brands typically source their clothing from countries such as China, Cambodia, India, Egypt, Indonesia, Morocco, Spain, Portugal, and Japan, among others. This approach is effective for well-established brands that can meet larger minimum order quantities (MOQs). These retailers often produce in the thousands and benefit from significant product demand. However, for those who are just beginning and exploring the market, accessing these countries for the creation of an initial collection may present challenges, as most manufacturers impose substantial MOQs. For individuals in the early phases of brand development, it is advisable to start with smaller quantities. One of the most significant errors I observe among first-time founders is their tendency to produce large quantities of products before adequately testing the market. They often overlook the option of initially pursuing a wholesale strategy to gauge market interest, opting instead to manufacture from the ground up. This lack of thorough research frequently leads to substantial financial losses due to the production of unsellable inventory. Consequently, they may find themselves in a position where they must liquidate their stock at a considerable loss. In contrast to many other nations, Turkey stands out as one of the largest manufacturing hubs globally, with factories that supply renowned brands such as Max Mara, Zara, River Island, Nike, Asos, and Shein, among others. Additionally, Turkey’s advantageous geographic location facilitates rapid cross-border logistics, particularly beneficial for European brands that demand shorter lead times. For those based in the UK, it is feasible to travel to Turkey and return within the same day. As a result, manufacturing garments in Turkey may prove to be more economical than outsourcing production to other regions.

One of the most significant errors I observe among first-time founders is their tendency to produce large quantities of products before adequately testing the market. They often overlook the option of initially pursuing a wholesale strategy to gauge market interest, opting instead to manufacture from the ground up. This lack of thorough research frequently leads to substantial financial losses due to the production of unsellable inventory. Consequently, they may find themselves in a position where they must liquidate their stock at a considerable loss. In contrast to many other nations, Turkey stands out as one of the largest manufacturing hubs globally, with factories that supply renowned brands such as Max Mara, Zara, River Island, Nike, Asos, and Shein, among others. Additionally, Turkey’s advantageous geographic location facilitates rapid cross-border logistics, particularly beneficial for European brands that demand shorter lead times. For those based in the UK, it is feasible to travel to Turkey and return within the same day. As a result, manufacturing garments in Turkey may prove to be more economical than outsourcing production to other regions.

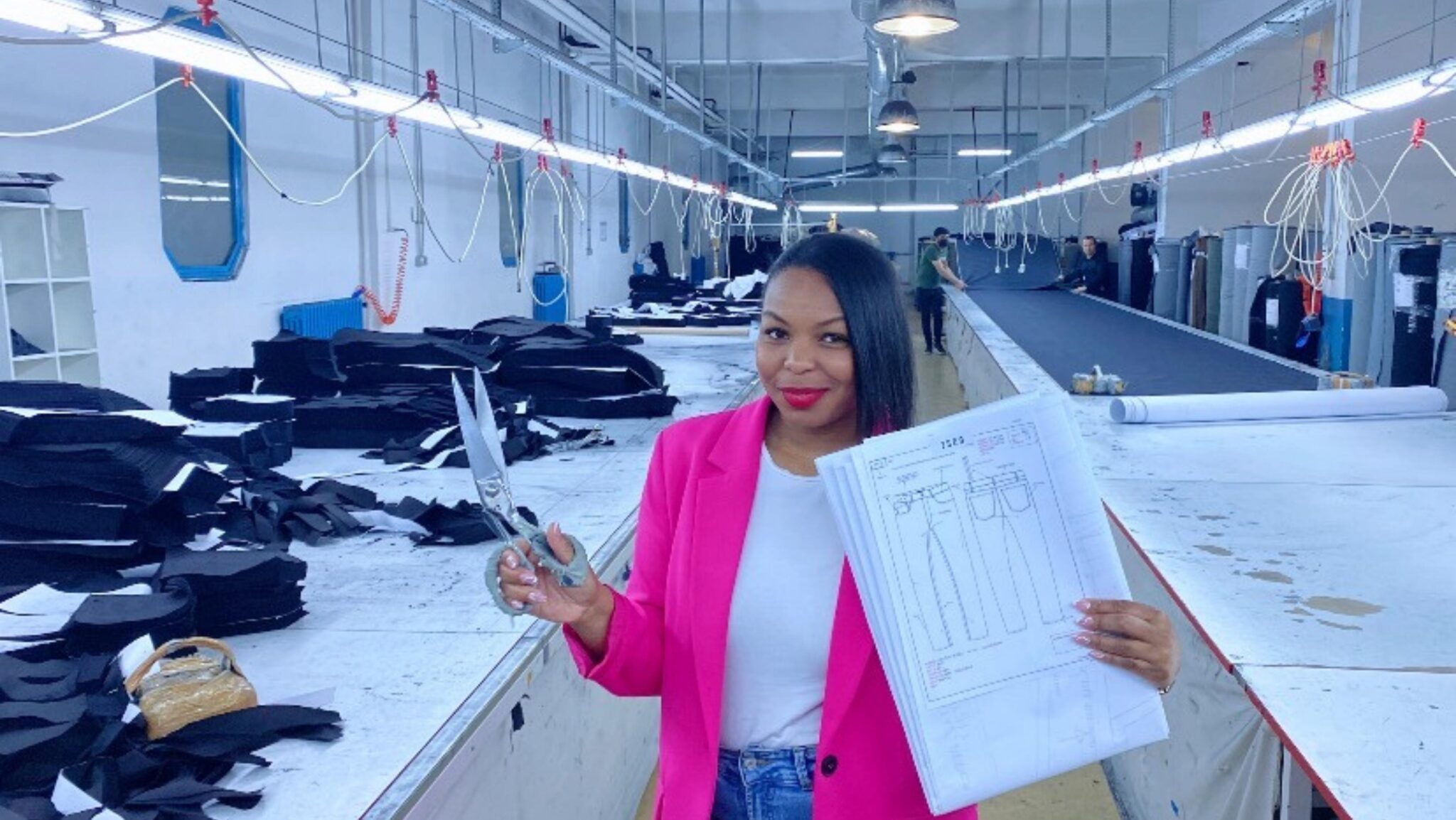

Manufacturers in Turkey demonstrate a remarkable degree of flexibility and willingness to collaborate with start-ups. They frequently accommodate lower minimum order quantities (MOQs), with many factories accepting orders as small as 100 pieces! Additionally, family-owned factories are open to conducting smaller test runs for initial orders. One aspect I particularly appreciate is their commitment to sustainability; excess materials from your initial collection are often preserved for future orders or repurposed into new products. Furthermore, Turkish manufacturers take great pride in producing garments of exceptional quality. I have encountered several factories that will not dispatch samples or approve garments until they meet their stringent standards, reflecting their meticulous quality control processes that instill confidence in the safety and reliability of your apparel.

How Do I Find A Good Turkish Manufacture?

The decision largely hinges on the specific type of garment you intend to create. If you have not yet done so, I encourage you to visit our YouTube channel, where I provide an in-depth look at the manufacturing process. Istanbul is home to numerous manufacturers, so it is advisable to take the time to evaluate those that specialize in your selected product(s). Additionally, do not hesitate to contact wholesalers. For instance, if you find a product from a wholesaler that you wish to include in your brand but require minor modifications, such as changes to the design or fabric, you can easily inquire about the possibility of a custom order; approximately 70% of them are likely to agree.

Manufacturer Screening

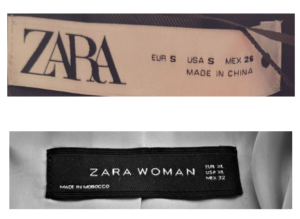

Ensure that you collaborate with factories that are experts in the production of your particular garment. It is illogical to approach a sportswear manufacturer for the creation of your haute couture dress line. Have you ever examined the labels of your preferred retail items to identify the materials used and origin? It is likely that each piece has been produced in a different country and the same principle applies to your brand. It is unrealistic to expect that all garments can be manufactured in a single country; any assertion to the contrary is misleading.

Zara’s production strategy illustrates the necessity of diversifying manufacturing locations, as it is unfeasible to produce all items within a single country. Different nations possess varying capabilities for garment production. For instance, the cost of manufacturing a bandage dress in Turkey may exceed that of producing the same item in Guangzhou, China. It is crucial to identify the specific garment intended for production and to determine which country offers the most favorable pricing, materials, and machinery for its creation. Engaging with any factory and requesting them to design an entire collection is not a viable approach. Caution is advised when dealing with manufacturers who assert they can produce any type of garment, as such claims are often unrealistic.

I recall the experience of designing tops for Modestwist, during which I was determined to have them produced in Turkey. I engaged with eleven different manufacturers, each of whom informed me that they were unable to create the tops due Turkey not having the fabric and machinery. To this day, I remain profoundly appreciative of their honesty and transparency. Many factories tend to be opportunistic, asserting their capability to produce items when, in reality, they cannot. This often leads to complications, including substandard products, poor production quality, and exorbitant costs, all stemming from a partnership with an unsuitable manufacturer. My recommendation is to invest time in thoroughly vetting and exploring various factories until you identify one that aligns with your specific needs.