Mainstream fashion brands tend to manufacture apparel from the likes of China, Cambodia, India, Egypt, Indonesia, Morocco, Spain, Portugal, Japan the list goes on. This works well for more established brands that have larger MOQs. These retailers are producing in the thousands, not to mention they have a huge product demand. However, if you’re just starting and testing the market, the above countries may prove difficult to tap into when creating your first collection. Most manufacturers require large MOQs. If you’re in the early stages of developing your brand, starting small is always the best option.

The biggest mistake I see first-time founders making is producing huge quantities before testing out the market. They could have easily taken the wholesale route first to test the market rather than manufacturing from scratch, but due to poor research they ended up wasting huge amounts of money on producing stock they couldn’t sell. As a result, they end up liquidating their stock and making a significant loss. Unlike other countries, Turkey has one of the biggest manufacturing hubs in the world, factories here produce for leading brands as Max Mara, Zara, River Island, Nike, Asos, Shein the list goes on. Turkey’s strategic location also means super-fast cross-border logistics, especially for European brands that require quicker lead times. If you are based in the UK, you can fly to Turkey and come back the same day. Therefore, you may find manufacturing your garments in Turkey more cost-effective than outsourcing them elsewhere.

Manufacturers in Turkey are way more flexible and open to working with start-ups. They can often meet you halfway in terms of MOQs. Most factories in Turkey can accept orders as little as 50pcs. Yes, you read correctly 50pcs! Family-run factories are also willing to accept smaller order test runs. What I love the most is their sustainability practices. Excess material from your first collection is often saved for your next batch order or recycled to make other products. Turkish manufacturers also pride themselves in solely producing high-quality garments. I have met several factories, who will not send out samples or even approve garments until it’s up to their satisfaction, their rigorous quality control processes are impeccable and provide a sense of ease and comfort knowing your apparel is in safe hands.

So How do I find A Good Turkish Manufacture?

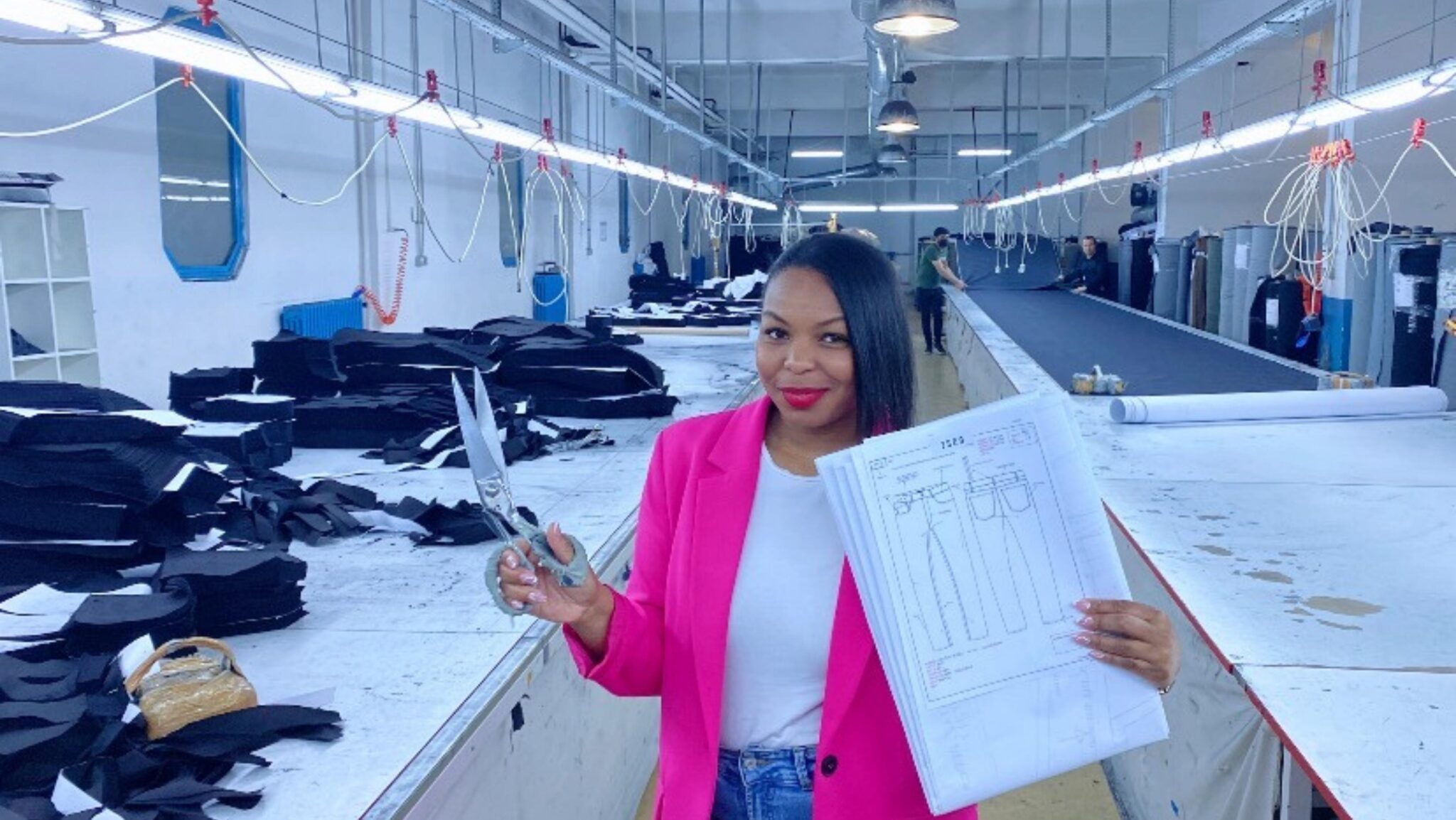

It honestly depends on what type of garment you are looking to produce. If you haven’t already, check out our YouTube channel, where I take you on a behind-the-scenes journey of the manufacturing process. There are hundreds of manufacturers within Istanbul, so spend time screening the ones specialising in your chosen product(s). Don’t be afraid to also reach out to the wholesalers. Let’s say there is an item in the wholesaler you really like and want to stock for your brand but require slight adjustments, such as the design or fabric. You can easily reach out and ask if they can provide a custom order, 70% off them will say yes!

Manufacturers in Turkey are way more flexible and open to working with start-ups. They can often meet you halfway in terms of MOQs. Most factories in Turkey can accept orders as little as 50pcs. Yes, you read correctly 50pcs! Family-run factories are also willing to accept smaller order test runs. What I love the most is their sustainability practices. Excess material from your first collection is often saved for your next batch order or recycled to make other products. Turkish manufacturers also pride themselves in solely producing high-quality garments. I have met several factories, who will not send out samples or even approve garments until it’s up to their satisfaction, their rigorous quality control processes are impeccable and provide a sense of ease and comfort knowing your apparel is in safe hands.

So How do I find A Good Turkish Manufacture?

It honestly depends on what type of garment you are looking to produce. If you haven’t already, check out our YouTube channel, where I take you on a behind-the-scenes journey of the manufacturing process. There are hundreds of manufacturers within Istanbul, so spend time screening the ones specialising in your chosen product(s). Don’t be afraid to also reach out to the wholesalers. Let’s say there is an item in the wholesaler you really like and want to stock for your brand but require slight adjustments, such as the design or fabric. You can easily reach out and ask if they can provide a custom order, 70% off them will say yes!

Work with factories that specialise in your garment:

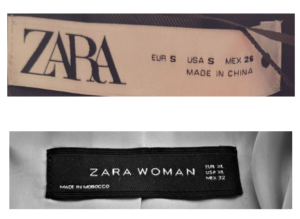

Make sure you’re working with factories specialising in your actual garment. It makes no sense to reach out to a sportswear manufacture asking them to produce your haute couture dress collection. Have you ever been to your favorite retailer and checked the labels, to see what material was used and the country in which it was produced? Chances are, each item has been manufactured in a different country and the same applies to your brand. It’s impossible for all garments to be produced in one country and if anyone tells you otherwise, they are lying..

Zara Example:

Some Of Zara’s jeans are made in Turkey

Some Of Zara’s jeans are made in Turkey

Some Of Zara’s Dresses are made in China

Notice how Zara does not produce everything in one country, because it’s impossible. Not all countries are equipped to produce certain garments. Getting a bandage dress made in Turkey can be more expensive than if were to be produce in Guangzhou (China). It’s imperative to establish which garment you want to produce, and which country has the best price points, materials, and machinery to even create your item. You can’t just work with any factory and ask them to design your collection. Beware of manufacturers who claim they can produce anything and everything, it’s very unlikely.

I remember the process of designing tops for Modestwist, I was adamant about getting them made in Turkey. I met a total of eleven different manufacturers who explained they could not design the tops because they did not have the raw material or the right machinery to create such products. Till this day I am super grateful for their honesty and transparency. Most factories can be greedy, claiming they can produce something knowing they can’t. This is when problems arise, as poorly made items, bad production, and extortionate cost all because you worked with the wrong manufacturer for your product. My advise is take your time screening and shopping around for factories until you find the one that best serves your requirements.